MTD Digital

Why is this good for you?

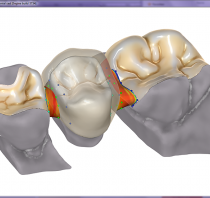

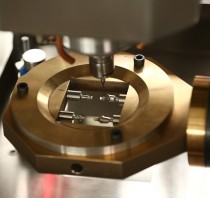

The digital revolution has taken over the world of dental medicine. Computer Aided Design (CAD) and digital production of crowns (CAM) prevent inaccuracies and are the future of the dental industry. The process begins with impressions or models of 3D scanning , after which the final crowns, bridges and bars are planned and designed using an imaging software, then sent to milling machine that mills the pre-designed model that was planned from CrCo, wax, PMMA, PEEK, zirconia, titanium or e-max (lithium disilicate) disks without human intervention.

Who should use it and why?

The advanced digital system supplies innovative solutions for dental laboratories, dentists and dental practices which allow manufacturing of works that could not be produced by using the existing means. The outcome is an expanded products portfolio that a business can offer with higher productivity and better quality. In addition, the total time from the impression taking till the application of the crown in the patient's mouth is being significantly shortened with significant cost reductions and increasing of the profits. The laboratories and dental practice that enter the digital arena will be able to meet the changing market requirements, become more efficient and competitive.

The purchase of a digital system requires a considerable financial investment. MTD assists with performing a feasibility study and tailor made system configuration according to the customer needs before the decision taking in order to lead the customer to take the wisest and best investment for him economically. Tailor made deal fit to your needs is a highest priority for MTDMTD and there will not be “forcefully pushing a digital system to a customer”. For players in the dental industry this can be a new growth engine.

Our values lead us

Our main value at MTDMTD is not doing business at any cost. We do not make deals that are suitable only for us, but rather deals that are good first and foremost for the customers. This is the philosophy that we chose being the result of many years of life experience. This value is a part of our business DNA at MTD being a significant component in the training process of the Company's employees who are responsible for its implementation. The decision to purchase digital systems requires an economic feasibility study. MTDMTD assists in tailor-making the deal to the customer's requirements while weighing the odds against the risks.

Components of the digital system

Scanner, design software, milling machine, sintering furnace. As with any system that is comprised of a number of parts, the quality of the final result is only as good as the lowest common denominator, meaning, the component in the system that gives the lowest relative quality result. Each one of the system components is important and the quality of the final work that is measured in microns very much depends on these system components. It is not enough to purchase a quality scanner, a quality milling machine or a quality furnace, but rather it is important to build a system in which the level of each one of its components is at the same level as the other components in the system.